Laser yekucheka tekinoroji ndeye yakazara-tekinoroji tekinoroji, iyo yakasanganisa yekuona, zvinhu sainzi neinjiniya, kugadzira michina, nhamba yekudzora tekinoroji uye tekinoroji yemagetsi uye mamwe maitiro, parizvino, ndiyo nzvimbo inopisa inowanzoitika kunetseka kwesainzi & tekinoroji munda uye maindasitiri. denderedzwa, kumba nekune dzimwe nyika.Kweanopfuura makore makumi mashanu, Laser kugadzirisa uye kunyorera kuri kukurumidza kukurumidza, kwakabatana neakawanda chirango fomu mune akati wandei echikumbiro chakaiswa, uye Laser main processing matekinoroji anosanganisira: laser yekucheka, laser welding, laser yekumaka, laser drilling, Laser kupisa kurapwa, laser. kukurumidza prototyping, laser coating uye zvichingodaro.

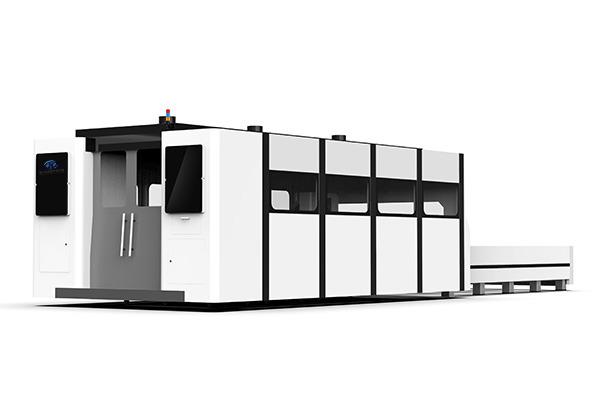

Laser yekucheka tekinoroji ndiyo yakanyanya kushandisa laser tekinoroji muindasitiri.Iyo inomhanyisa shanduko yechinyakare yekugadzirisa indasitiri uye inopa nzira nyowani yemazuva ano maindasitiri kugadzirisa.Yakave inonyanya kushandiswa laser yekugadzirisa nzira muindasitiri yekugadzira maindasitiri.Parizvino, laser yekucheka tekinoroji yakashandiswa zvakanyanya mukugadzira michina, kuvaka bhiriji, sheet simbi kugadzirwa, ngarava nekugadzira mota, magetsi nemagetsi indasitiri, avhiyesheni uye aerospace uye mamwe ehupfumi mbiru maindasitiri.Nekuenderera mberi kwesainzi uye tekinoroji uye mashandisiro, laser yekucheka tekinoroji ichaenderera mberi mune dzimwe nzvimbo.

Mumakore achangopfuura, laser processing tekinoroji iri kukura nekukurumidza.Kushandiswa kwayo kuri kuramba kuchiwedzera.saka iyo laser inozivikanwa se "universal processing tool" uye "remangwana rekugadzira system common processing means".Tekinoroji yekugadzirwa kwenyika dzepamusoro maindasitiri iri kuita shanduko yemhando nekuda kwekushandiswa kwakakura kwelaser processing tekinoroji.Laser yekucheka tekinoroji ndiyo yakanyanya kushandisa laser tekinoroji muindasitiri.Yakasimudzira shanduko yechinyakare indasitiri yekugadzira uye yakapa nzira nyowani dzemazuva ano maindasitiri ekugadzirisa.Yakave inonyanya kushandiswa laser yekugadzirisa nzira muindasitiri yekugadzira maindasitiri, inogona kutora iyo yese laser processing indasitiri kupfuura 70%.

Laser yekucheka iko kushandiswa kweyakatarisana nepamusoro simba density laser danda inoisa iyo workpiece.Pasi pechimiro chekupfuura laser chikumbaridzo chelaser simba density, laser beam simba uye inoshanda gasi inobatsira kucheka maitiro akasungirirwa kemikari reaction heat zvese zvinonyudzwa nezvinhu.Tembiricha yelaser action point inokwira zvakanyanya uye mushure mekubikira kwasvika, zvinhu zvinotanga kunyungudika uye kugadzira gomba.Nekufamba kwehama kwechiedza danda uye workpiece, zvinhu zvinozopedzisira zvaumbwa kuita mutswe.Sediment iri pakatsemuka inopeperetswa nerimwe gasi rinobatsira.

Laser yekucheka ine mabhenefiti akawanda akadai sehupamhi hwekucheka, kukurumidza kucheka, kutsemuka yakamanikana, yakanaka yekucheka mhando, diki kupisa kwakakanganisika nzvimbo, pamwe nekuchinjika uye etc. Izvi zvakanakira zvave zvakakura kwazvo zvekushandisa muindasitiri yemazuva ano.Laser yekucheka tekinoroji yavewo imwe yeakanyanya kukura matekinoroji mune laser processing tekinoroji.Kuenzaniswa nemamwe mwenje, heano mamwe maitiro seanotevera:

1. Kupenya kwepamusoro

2. Kutungamira kwepamusoro

3. High monochrome

4. Kubatana kwepamusoro

Zvakare nekuda kweaya maficha mana, yakashandiswa zvakanyanya, uye yakaunza akakosha maficha kune anotevera echinyakare kugadzirisa kune laser processing:

(1) Sezvo pasina kusangana kugadzirisa, uye iyo laser beam simba uye kumhanya kwekufamba kunogadziriswa.Saka iwe unogona kuwana zvakasiyana-siyana zvekugadzirisa.

(2) Inogona kushandiswa kugadzira zvakasiyana-siyana zvesimbi, kwete-simbi.Kunyanya, inogona kugadziriswa yakakwira kuoma, yakakwirira brittleness uye yakakwirira melting point yechinhu.

(3) Iko hakuna "chishandiso" chinopfeka panguva yekugadziriswa kwelaser, uye hapana "simba rekucheka" rinoshanda pane workpiece.

(4) Laser kugadzirisa kweiyo workpiece kupisa kwakakanganisika nzvimbo idiki, diki deformation yeworkpiece, kutevera-up kudiki kwekugadzirisa.

(5) Iyo laser inogona kugadzirisa workpiece mumudziyo wakavharwa kuburikidza nepakati pepakati.

(6) Laser iri nyore kutungamira.inogona kuwanikwa munzira yekushandura kuburikidza nekutarisa.Zviri nyore kwazvo kushanda pamwe neCNC system yekugadzirisa zvikamu zvakaoma.Naizvozvo, laser kucheka inzira inoshanduka yekucheka.

(7) Laser processing ine yakakwirira kugadzirwa kunyatsoita.Kugadziriswa kwemhando yakagadzikana uye yakavimbika, yakakosha yehupfumi uye yemagariro mabhenefiti.

Nguva yekutumira: Jan-04-2021