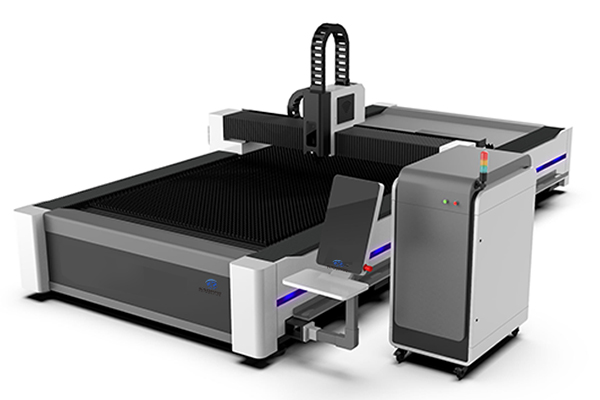

1. High precision yekucheka: laser cutting machine positioning kururamisa kwe 0.05mm, kudzokorora kumira kwe 0.03 mm.

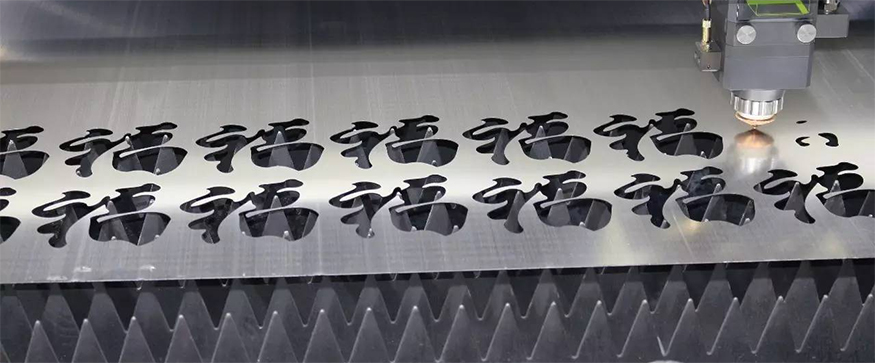

2. Laser yekucheka muchina yakamanikana kerf: kutarisisa danda relaser munzvimbo diki, nzvimbo yekutarisa kuti iwane yakakwira simba density, zvinhu zvakakurumidza kupisa kusvika padhigirii re vaporization yakanyungudika kuita makomba.Nedanda uye zvinhu zvine mutsara, zvekuti maburi anoramba achiumbwa kuburikidza neakamanikana, incision hupamhi inowanzo 0.10-0.20mm.

3. Laser yekucheka muchina yakatsetseka yekucheka pamusoro: hapana burr yekucheka pamusoro, kucheka kwepamusoro roughness ye general control mukati meRa6.5.

4. Laser cutting machine speed: kucheka kukurumidza kusvika 10m / min Maximum positioning speed kusvika ku 30m / min inokurumidza kukurumidza kudarika mutsara wekucheka.

5. Yakanaka mhando laser yekucheka muchina: sag isingabatanidzi yekucheka, kuchekerera kupisa hakuna mhedzisiro, zvakanyanya hapana workpiece thermal deformation, kudzivirira zvachose zvinhu zvinoumbwa kana uchibaya, slit kazhinji haidi yechipiri kugadzirisa.

6. Usakuvadza workpiece: laser yekucheka musoro haisi kusangana nepamusoro pezvinhu kuti uone kuti usakwenya workpiece.

7. Haisi kukanganiswa nechimiro chebasa rekushanda: laser processing inoshanduka, uye inogona kugadzirisa chero mifananidzo, inogona kucheka mapaipi uye mamwe maprofayiri.

8. Laser yekucheka michina inogona kucheka zvakasiyana-siyana zvekugadzirisa zvinhu: zvakadai sepurasitiki, huni, PVC yeganda, machira, girazi nezvimwe zvakadaro.

9. Kuchengetedza mari yekudyara mold: laser processing pasina mold, hapana mold kushandiswa, kwete kugadzirisa mold, mold replacement saving time, kuchengetedza mari yekugadzirisa, kuderedza mari yekugadzira, kunyanya kugadzira zvigadzirwa zvakakura.

10. Kuchengetedza zvinhu: purogiramu yekombiyuta, inogona kutemwa mumhando dzakasiyana, kuwedzera kushandiswa kwezvinhu.

11. Wedzera kukurumidza kwefekitari yemuenzaniso: mushure mekugadzirwa kwemifananidzo yezvigadzirwa, laser processing inogona kuitwa pakarepo, kuwana mhando yezvigadzirwa zvitsva munguva pfupi.

12. Kuchengetedza uye kuchengetedzwa kwezvakatipoteredza: laser processing tsvina, ruzha rushoma, yakachena, yakachengeteka, isina kusvibiswa, inovandudza zvikuru nzvimbo yekushanda.

Nguva yekutumira: Jan-04-2021