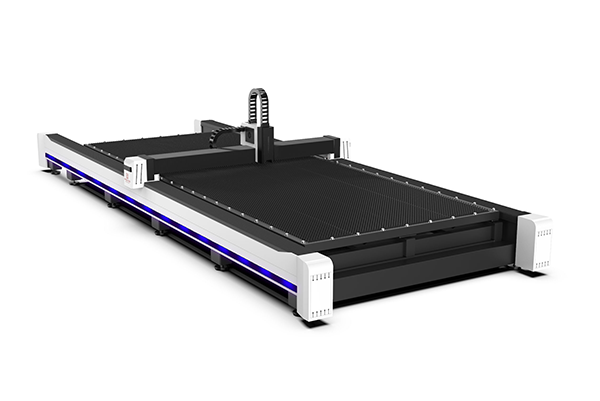

Mune mamwe maindasitiri anorema esimbi ekugadziridza, akadai seindasitiri yekuvaka ngarava, muchina wemigodhi, uye muchina wekuvaka, matambudziko akadai anowanzosangana: nzira yekuwana yakasimba welding yezvikamu zvesimbi nesimbi zvikamu?Kazhinji, zvikamu zvesimbi zvicharatidza nzvimbo yakachekwa mushure memaitiro ekucheka.Kuti uite kuti zvikamu zvekubatanidza zvezvikamu zvakasungirirwa zviwedzere kubatanidzwa, zvakakosha kugadzirisa mabheji emhando dzakasiyana-siyana dzejometri pamicheto yezvidimbu zviviri zvesimbi, uye wozoita kupera kwechiso.Munguva pfupi yapfuura, Knoppo yakaparura KP Series (simba kubva pa30000W kusvika 8000W) Sheet.fiber laser bevel yekucheka muchina, iyo inogadzirisa matambudziko akadaro ekushongedza, kuderedza maitiro akaoma, uye zvakanyanya kuchengetedza nguva uye mari.

Pamberifiber laser kuchekatekinoroji, tekinoroji yekucheka tekinoroji yakashandiswawo musimbi mashizha ekugadzirisa nzira dzakadai semurazvo uye kucheka kweplasma.Nekudaro, iyo yechinyakare murazvo yekucheka nzira inoburitsa yakadzika kucheka, uye kune yakaoma groove trajectories, hunyanzvi uye kushanda kwevashandi kunoda kuve nehunyanzvi, uye kuwirirana kwewelding hakugone kunyatsogutsikana;plasma yekucheka Yakakura, zvichikonzera kuderera kwechimiro, uye njodzi dzakadai searc radiation, utsi uye ruzha zvichagadzirwa panguva yekucheka.

Mhando mbiri dziri pamusoro dzekucheka nzira ndedzeiyo hombe yekupisa sosi yekuisa nzira yekugadzirisa.Iyo ndiro ichave yakaremara nemafuta pasi peiyo thermal processing nzira, uye inverse deformation process inoda kugadziriswa mushure mekugadzirisa kwapera.Kuenzaniswa neyechinyakare beveling nzira, laser inzira nyowani yekugadzirisa ine diki deformation yekupisa, yakanakisa incision mhando, iyo yepamusoro-soro kurongeka uye kugadzikana kwakanyanya mumusika.

Knoppo KP seriessheet fiber laser beveling yekucheka muchinainogona kuvandudza zvakanyanya kusimba kwewelding, welding fusion uye workpiece aesthetics kuburikidza nekugadzirisa groove yeimwe geometric shape mu-to-be-welded chikamu cheweldment.Kune alloy simbi, iyo groove inogona zvakare kuita basa mukugadzirisa chiyero chesimbi yepasi uye yekuzadza simbi.

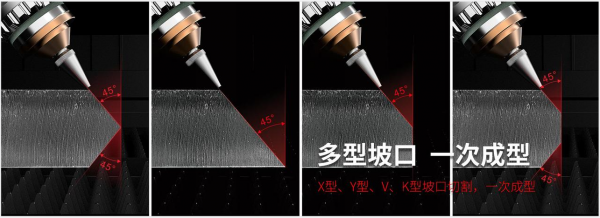

Zvinoenderana nehupamhi hwakasiyana uye hwemuviri zvimiro zvemahwendefa akasiyana, kusarudzwa kwebeveling mafomu kwakasiyanawo.Mafomu ekubhejera akajairika pamusika anosanganisira X-shaped groove, V-shaped groove, Y-shaped groove, K-shaped groove, etc. Y-shaped groove uye V-shaped groove ndeye-single-sided welding, iyo iri nyore kucheka uye. post-welding process.Kana ukobvu hweweldment huchiwedzera, iyo K-shaped groove kana X-shaped groove inowanzo shandiswa.Paukobvu hwakafanana, huwandu hwesimbi weld inogona kuderedzwa neanenge 1/2, uye welding inoenderana, uye deformation mushure mekugadzira idiki.

Chii chinonzi knoppo fiber laser beveling yekucheka muchina?

Chekutanga, groove yeimwe geometric chimiro inogona kugadziridzwa yakananga kune-ku-we-welded chikamu cheweldment, kuitira kuti welding seam nekupinda kwakazara kwehupamhi hwewelding inogona kuwanikwa mune inotevera welding process, kuitira kuti uve nechokwadi. iyo welding simba re weldment uye kuderedza zvisingakoshi maitiro., kuwana mhedzisiro yakawanda;

Chechipiri, kana ichienzaniswa neyechinyakare murazvo uye plasma bevel processing, laser kugadzirisa inoshanda zvakanyanya uye inochengetedza zvinhu.Semuenzaniso, muindasitiri yekuvaka ngarava, kushandiswa kwelaser bevel yekucheka tekinoroji kugadzirisa T-yakaumbwa zvikamu zveyakaderera alloy simbi inogona kuchengetedza zvakanyanya alloy simbi zvinhu uku uchivimbisa kugadzikana kwechikepe;

Chechitatu, laser processing ine zvakanakira diki deformation yekupisa, yakagadzikana yekucheka mhando uye yakakwirira chaiyo.Kubatana kwakanaka.

Parizvino, Knoppo laser bevel yekucheka tekinoroji yakawana kufukidzwa kuzere mushizha simbi kugadzirisa uye profil process, uye tekinoroji ine huwandu hwakawanda hwekushandisa, inovhara kuvaka ngarava, maindasitiri mafiriji, michina yekuvaka, muchina wemigodhi, mapaipi emafuta, nezvimwe.

Nguva yekutumira: Jul-08-2022